KIENAST & HOLZNER

HIGH PRECISION TURNED PARTS

Kienast & Holzner produces high precision turned parts from 8-350mm and verarbeitet processes non-ferrous metals as well as any kind of steel.

OVERVIEW ABOUT OUR PRODUCTION

PRODUCTION

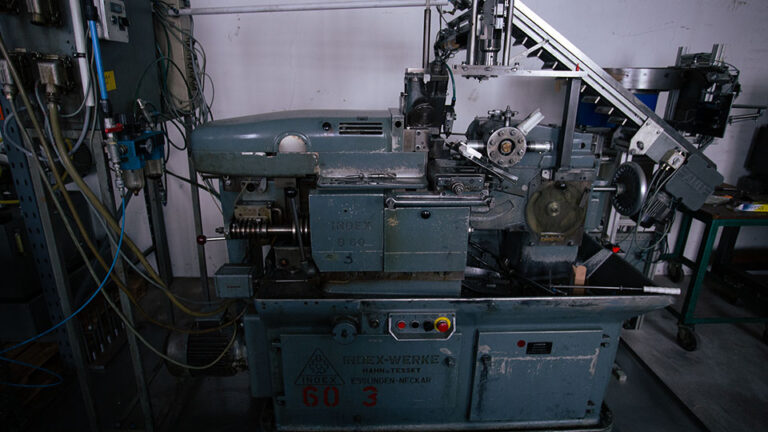

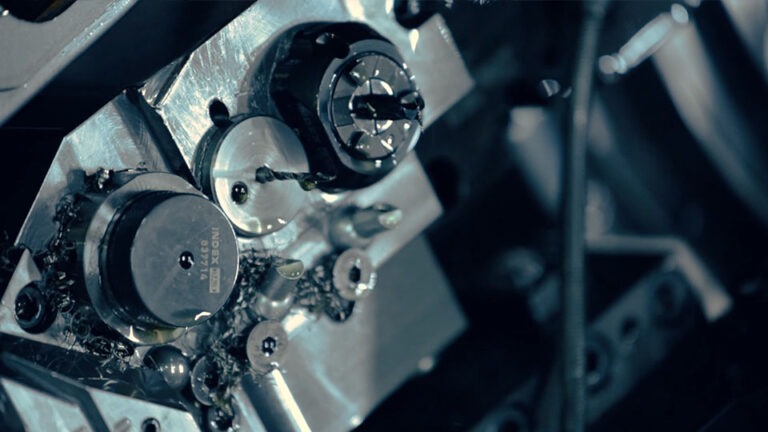

Machines

Latest CNC lathes, conventional lathes and rotary indexing machines with screw tap and milling units form our set-up.

8mm to 350mm

We produce high precision turned parts with diameters ranging from 8mm to 350mm.

Diversity of Materials

Process of all materials without restrictions: all non-ferrous metals, mild steels, high-alloy steels and stainless steels (e.g. 1.4301) and rotatable plastics.

Flexibility

Our streamlined production structure with state-of-the-art machinery allows us to respond quickly to customer requirements.

24/5 & All in-House

Our production runs 5 days a week in a 3-shift operation. Shipping and packaging are carried out with the utmost care.

Surface Coating

The collaboration with selected partners enables us to produce turned parts tempered and/ or surface coated by customer requesT

First-rate, reliable, Steady

QUALITY

Quality Inspection

Reliable processing up to a thousandth millimeter scope, ensured with a 3D Mahr Multiscope 250 measuring machine and an Optacom LC 10 contourgraph.

Refinishing

All parts get double checked by machines developed specially by us and by visual control.

Cleaning

Through our Pero cleaning system using modified alcohol as a cleaning agent, supported by ultrasonic technology, we not only protect the environment but can also meet the strictest cleanliness requirements. Upon customer request, the components can be preserved afterward.

our contribution

ENVIRONMENT

Recycling and reusing raw materials not only preserve the environment but also help to reduce costs from which our customers profit directly.

About us

THE COMPANY

First Austrian Gear Factory

Kienast & Holzner is a family owned company located in Vienna, Austria,. It was founded in 1950 and evolved from the First Austrian Gear Factory which was founded in 1896 by Rudolf Kienast. In the beginning the company focused on the production of electro mechanical special parts.

The Development

By time Kienast & Holzner more and more specialised in the production of high precision turned parts in mass production. In the 1970ies a plastic injection molding plant was integrated into the company's portfolio but was then shut down again in the early 2000s to create mor space for more CNC lathes.

On the Pulse of Time

Today, Kienast & Holzner is one of the leading manufacturers of high-precision turned parts in the DACH region. Equipped with state-of-the-art machinery, the company produces precision turned parts of the highest quality and reliability. This enables us to cover a wide spectrum from automotive to renewable energy

Joachim Venus

Managing Director

Mag. Andrea Maleh

Office

Riccardo Kolb

Quality Management

Gerlinde Ebner

Office

Dragan Zivkovic

Logistics

Questions? – we have answers

FAQ

As a supplier we are represented in a wide range of industries. We manged to establish ourselves as reliable partners in the automotive industry, heating-, security-, medical- and environmental technology, and even in the jewelry sector.

A sampling process with an initial sample inspection report according to VDA, PPAP with an IMDS entry is possible.

Heat treatment:

Case hardening, annealing, induction hardening, nitriding, nitrocarburizing, tempering, quenching, and tempering.

Surface finishing:

Galvanizing, nickel plating, anodizing, phosphating, bluing, silver plating.

Surface processing:

Polishing, deburring.

The packaging can be customized according to customer preferences. The range includes everything from simple cardboard to KLTs and even specialized packaging.

No, we do not.

how you find and reach us

LOCATION

ADDRESS

Seeböckgasse 4,

Vienna-1160,

Austria

CONTACT

Tel.: +43 1 486 33 26

Fax: +43 1 485 75 89

Email: office@kienast-holzner.com

OFFICE TIMES

07:00 AM – 04:00 PM

Monday – Thursday

Friday 07:00 AM – 11:30 AM